How Velvet Operations Group Solved Common Manufacturing Challenges: A Case Study

Introduction to Velvet Operations Group

In the ever-evolving world of manufacturing, maintaining efficiency and overcoming common challenges are crucial for success. Velvet Operations Group has established itself as a leader in providing innovative solutions to these complex issues. This case study explores how they tackled some of the most pressing challenges faced by manufacturers today.

Velvet Operations Group specializes in optimizing processes and improving productivity. Their approach combines cutting-edge technology with deep industry knowledge to deliver exceptional results. In this case study, we will delve into their strategies and the impact they have made on their clients' operations.

Challenge 1: Streamlining Supply Chain Management

One of the most significant challenges in manufacturing is managing the supply chain efficiently. Delays, errors, and miscommunications can lead to costly disruptions. Velvet Operations Group addressed this by implementing an integrated supply chain management system, which synchronized all aspects of the process from procurement to delivery.

This system offered real-time visibility into inventory levels and shipments, allowing for proactive decision-making and reducing lead times. As a result, clients experienced improved coordination with suppliers and enhanced customer satisfaction through timely deliveries.

Key Benefits of the Integrated System

- Real-time tracking: Enhanced visibility into inventory levels and movements.

- Improved supplier relations: Streamlined communication and collaboration.

- Reduced operational costs: Minimized waste and inefficiencies.

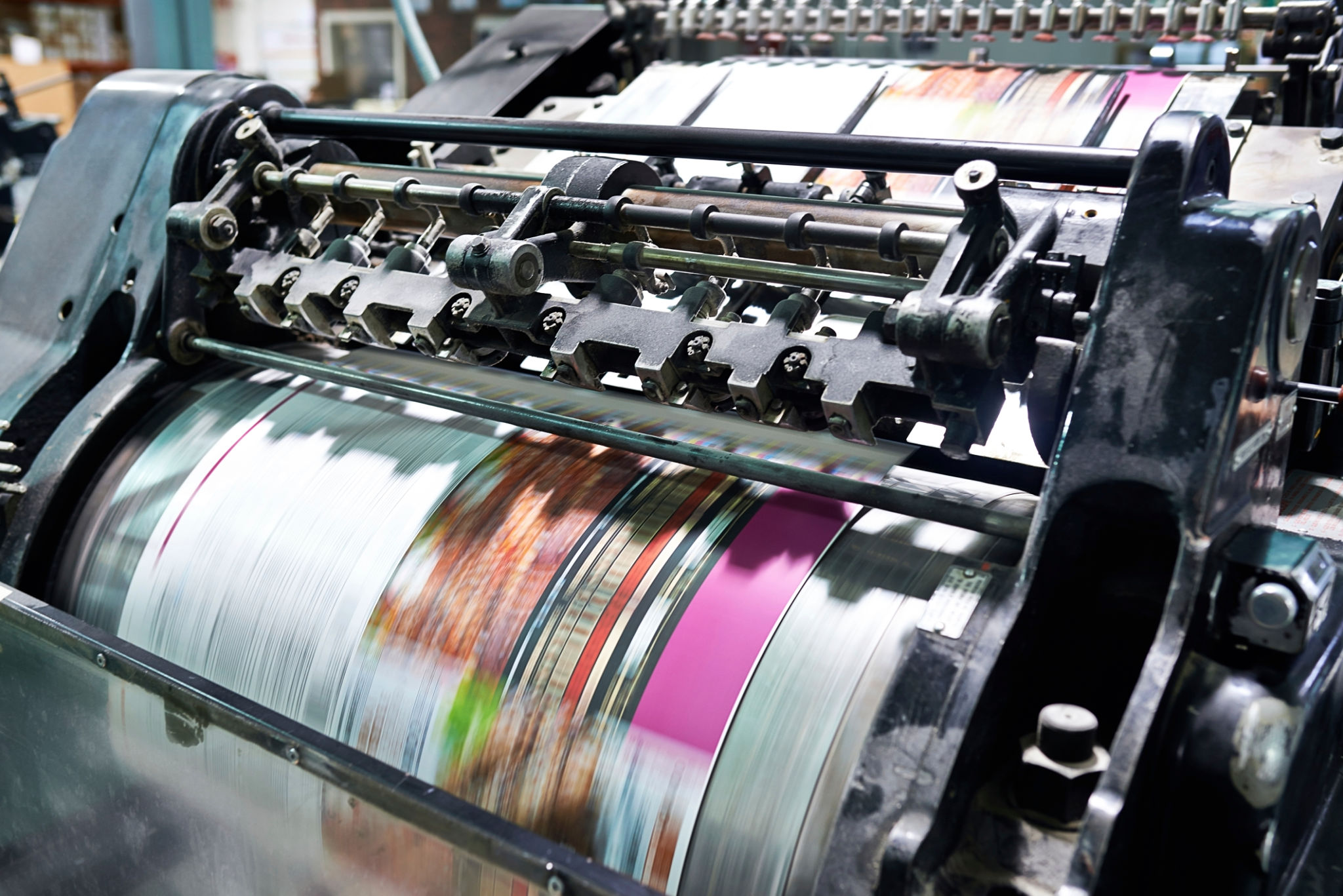

Challenge 2: Enhancing Production Efficiency

Another common issue in manufacturing is boosting production efficiency without compromising quality. Velvet Operations Group tackled this by implementing advanced automation technologies and lean manufacturing principles. This approach not only increased output but also maintained high quality standards.

The introduction of smart machinery and AI-driven analytics allowed manufacturers to optimize their production lines. Velvet Operations Group's solutions led to a significant reduction in downtime and waste, further driving profitability for their clients.

Results Achieved

- Increased output: Production rates improved by up to 30%.

- Quality assurance: Consistent product quality maintained through rigorous standards.

- Cost savings: Dramatic reduction in production-related expenses.

Challenge 3: Workforce Training and Development

The rapid advancement of technology in manufacturing necessitates a skilled workforce capable of operating complex machinery and systems. Velvet Operations Group recognized this need and developed comprehensive training programs tailored to each client's specific requirements.

The training programs focused on upskilling employees, ensuring they were well-versed in the latest technologies and best practices. This investment in human capital not only improved operational efficiency but also enhanced employee satisfaction and retention.

Impact on Workforce

- Enhanced skills: Employees equipped with cutting-edge knowledge.

- Increased retention: Reduced turnover through employee engagement.

- Improved morale: Empowered workforce contributing to organizational goals.

Conclusion

Through strategic interventions and innovative solutions, Velvet Operations Group has successfully addressed common manufacturing challenges, transforming operations for their clients. By streamlining supply chain management, enhancing production efficiency, and investing in workforce development, they have set a benchmark for excellence in the industry.

Their commitment to continuous improvement and tailored solutions ensures that Velvet Operations Group remains at the forefront of manufacturing advancements, driving success for their clients in an increasingly competitive landscape.